Project manufacturing

A detailed description about how VVS Prefab uses RamBase to manage their project oriented production

TABLE OF CONTENTS

Part one: It all starts with a lead

VVS Prefab manufactures tailormade, technical heating and cooling systems, cabinets, and MEP corridor racks for large plumbing vendors. The products are prefabricated by VVS Prefab so that the plumbing vendors can install the solutions easily and effectively on site. The start of a project for VVS Prefab begins with a potential customer lead registered in RamBase.

Organizing the sales process

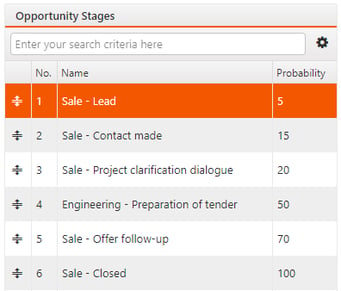

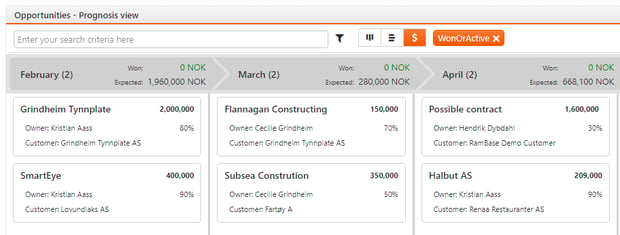

For VVS Prefab the initial customer contact starts either by entering a tender process for a project, or the customer reaches out directly. All customer leads are registered as an opportunity in the CRM-module in RamBase. The CRM-module (short for Customer Relationship Management) is an application that, besides holding all key information about your customers and contacts, also follows business opportunities through the different stages from lead to final deal.

Each step in the process has defined features such as customer contact information, internal lead responsible, expected value of the lead (choose either one-off revenue or recurring, periodic income) and the probability of successfully closing the order. By using the CRM module in RamBase, VVS Prefab have a good overview over the various offers they have sent out and where in the process they are with each of their customers.

An example on how the CRM-module in RamBase delivers a project overview.

Involving department expertise

A department rarely works alone on a project. At some point specific department knowhow needs to be included into the project to move it forward. For VVS Prefab, this happens when a customer asks for an offer. The request goes straight to the technical department for their calculations, design sketches and quality assurance. When the calculations are ready, an offer is sent from the system that includes technical details and design. Then the responsibility and further customer follow-up, goes back to the sales department.

When several departments and employees are involved in a project it can be difficult and time-consuming to communicate project-updates and assign project-tasks. With RamBase, all departments work in the same system and this gives VVS Prefab a single overview of a project and the control they need to manage multiple projects.

All tasks documented

All tasks documented

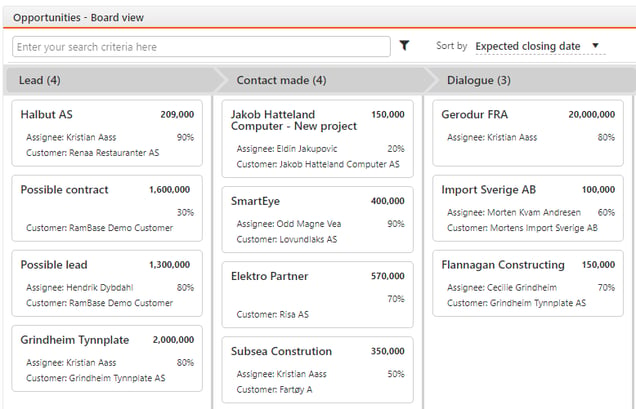

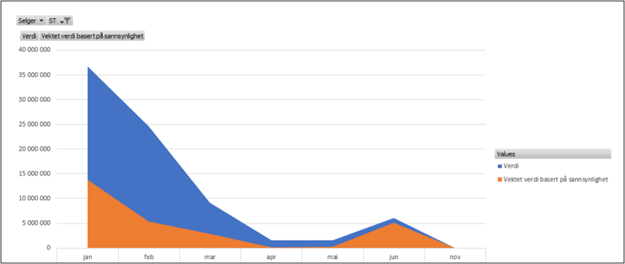

Sharing a system, the task functionality becomes an invaluable tool. VVS Prefab have created several task-processes to systemize all the different task that have to be documented during a project. One example is the “Bid process” that is generated by the project manager when a lead is registered. The different department managers involved in the project receive their assigned task for handling the bid. They can then delegate the tasks onwards to any employees in their department that have spare capacity.

The processes are based on previous experience and can be updated while the project is ongoing to incorporate for new learnings and ideas. Updating the system with continuous improvements is important, since it moves the company away from depending on individual employee knowledge.

The task process in RamBase is an intuitive and easy to use feature. The Project Manager can oversee the assigned task for a project, review deadlines and change task responsibility, if a person is unable to perform the task.

Task processes are not limited to project related tasks. This is an HR-related example for onboarding a new employee.

Integrating key sales specifics

VVS Prefab had to make some choices regarding their way of working and how RamBase operates. All companies operate slightly differently and to customize an ERP system to offer identical processes to those you are used to, would be a time consuming and costly consulting exercise. The key is to find a system that delivers on the core processes of your business and with good integration solutions that manage the rest.

For VVS Prefab, RamBase was a good fit for the main processes they needed, such as finance, procurement, manufacturing, logistics, documentation, quality, CRM and sales. For the sales department, there were some sales information that the system did not deliver out of the box. It is a faux pas to mention Excel spreadsheets when talking about ERP. However, if this is information that you are used to having, exporting to Excel can be done. It provides a quick and inexpensive solution to get you up and running, before considering making it an application in the system.

For example, each night an external sales spreadsheet is updated with information from the CRM module in RamBase. The spread sheet handles information regarding individual sales teams’ performance and is an important tool for management follow-up in VVS Prefab. This integration shows how RamBase can be flexible to accommodate tailormade functionality, without losing the integrity of the system and going overboard with customization projects in the beginning.

Part two: Let's design the Product

"Complex" is a fitting description for the many products that VVS Prefab manufacture. Their products are tailor-made based on the requirements and specifications set by their customers. From large technical heating and cooling systems to a series of intricate pipe-cabinets, VVS Prefab needs a system that can handle all the different parts and operations required to effectively build their products.

Handling a complex Bill of Material

Handling a complex Bill of Material

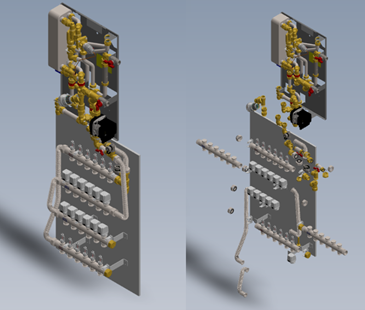

One type of product VVS Prefab manufactures is technical cabinets. An example of such a cabinet can be viewed in the picture below. This cabinet consists of several components that are unique for one specific customer’s request. Handling the product’s Bill of Material (BOM) is a key strength in RamBase and makes intricate products easy to manage. It boils down to creating order in the chaos of different parts and operations needed to build up a product.

The cabinet assembled on the left, and the same cabinet with all the different parts disassembled.

In RamBase, a product will be given a structure which consists of a combination of components, sub-assemblies, and operations. These sub-assemblies can also be product structures that include more components, operations, and even more sub-assemblies. With RamBase there are no limits to how many structure levels the system can handle. In other words, there are no limits to the complexity of the BOM that RamBase can handle.

Watch the video: Step by step guide on how to create a product structure

Controlling all changes

There will always be changes to a project. Maybe the customer has new ideas, or some external factors affect access to some material or parts. In RamBase it is easy to change the different parts in your product structure as you move along in the sales process. Every new version is tagged to the relevant sales document, making it easy to know what version have been sent at each stage of the sales process.

Thinking more long-term regarding changes, the question concerning outsourcing part of the manufacturing process arises. VVS Prefab have always had a focus on margin control when it comes to their products. They have seen the positive effect of considering other options for different sub-assemblies in their products. All the while never compromising on quality. Changes will often affect cost, price, and margin of your product. RamBase has useful features that lets you easily calculate the impact any changes will have on your sales price and margin, such as the sales calculator.

Watch the video: The benefits of the Sales Calculator in RamBase.

Part three: Managing the Order

When the product design is approved by the customer and the product structure is defined in the system, the project enters a new phase with an active order. The sales team in VVS Prefab can now concentrate on new leads, rest assured that the active order will seamlessly generate both procurement- and production orders in RamBase.

Efficient purchase handling

The main reason why VVS Prefab chose RamBase was the need for an efficient purchasing tool. Take for example stock control: It is costly having too many items in stock, but you cannot run out either. Another example of inefficient purchasing is sending multiple orders to a supplier for the same component for different projects. Having the system identify the possibility to bundle orders together and gain potential discounts is good for the bottom line and the environment. RamBase identifies all these concerns for VVS Prefab, giving them an efficient purchasing tool to manage multiple projects simultaneously.

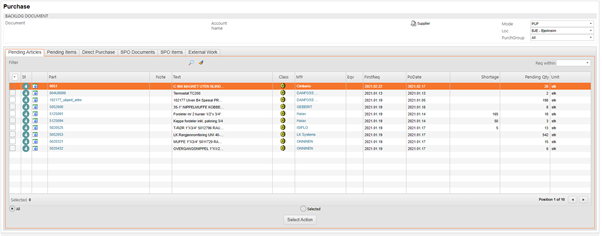

All purchasing needs are registered in the procurement application, sorted by internal processing date. This overview is the go-to place for the procurement department to know the lay of the land with regard to stock requirements and availability. The list will be updated automatically when stock is below the desired minimum quantity level or if sales orders or production work orders cannot be fulfilled due to lack of goods.

Example of all purchasing needs in the company updated in one window

Smart features in RamBase save VVS Prefab valuable time. Such as sorting purchasing needs towards one supplier from the overall list and using select all. Then a new purchase order will be automatically generated and completed with the information you need. The orders are not locked, you can manually add more items, change dates etc. In a perfect world there would be no need for interference, but a rigid system that does not allow for quick intervention is not a perfect solution.

The purchase application in RamBase has given the procurement department in VVS Prefab a more efficient way of working. Previously, their main job was to actively collect information, now it’s all stored in the system and their job is more focused on making strategic purchasing decisions.

When the relevant items are delivered from the suppliers, all items go through a goods received process. When the items have passed the quality control, they are placed in stock locations based on the specific need. Project-specific items are placed in separate locations in the warehouse or delivered directly to the relevant workstations. The system is kept up-to-date with all the information the warehouse operators need to progress the order.

Smart production management

Same as for the procurement application, the Production Manager has a go-to list in RamBase with all the active production work orders. VVS Prefab have registered all their workstations in RamBase. The system then sets up an individual list with production work orders per station. That way workstation owners can organize their time themselves without having to rely on attending daily workshop meetings or follow printed out paperwork orders to know what is expected of them.

VVS Prefab manufacture items based on individual customer projects and the list in RamBase is updated when new sales orders are registered. For companies with a make-to-stock model, the production list will be triggered when items go under the minimum stock level. No need to manually count items or follow up regularly, the system automatically takes control and corrects the number of items needed.

A complex product may consist of multiple work orders. The system identifies the work orders that are ready to be manufactured and which are waiting for parts or other production orders. This division creates an effective production for VVS Prefab and lets them combine working on several projects at the same time. If something interferes with the delivery time of the project, the system will give a warning. The warning can be triggered by several aspects, such as not enough capacity at one or more machines, delivery time of certain items or not enough time to complete the production time required for the project in the time available. With an effective production planning system like RamBase, the Production Manager’s role is not micro-managing, but to rather oversee all the production orders and find solutions to potential bottlenecks and late deliveries.

Watch the video: Inspecting production needs and creating production work orders.

Part four: Control during the Project

Managing multiple projects with different customers and unique product specifications requires a system that can turn all that information into user-friendly workspaces for the different employees in your organization. From workshop operators to project supervisors to the management team; the key is to bring real-time information to each employee.

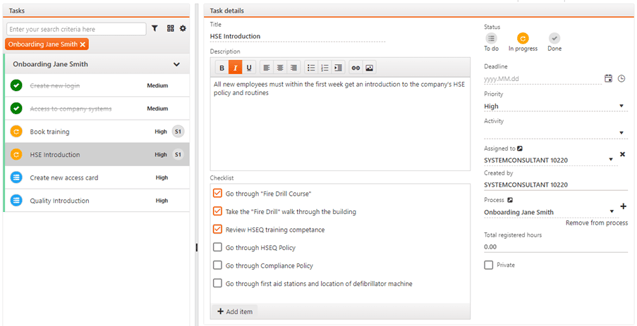

Real-time overview

Getting a real-time overview of what’s happening in a company is important. Enriching that overview with information about expected and realized revenue each month is vital. With the CRM solution in RamBase the sales team in VVS Prefab have total control over all active leads. Other departments can follow the progress and be notified when required. And finally, the management team gets the overall real-time financial information they need to see that the company is moving in the right direction.

Example of an CRM opportunity board with prognosis view per month

Following up the financial side of the project

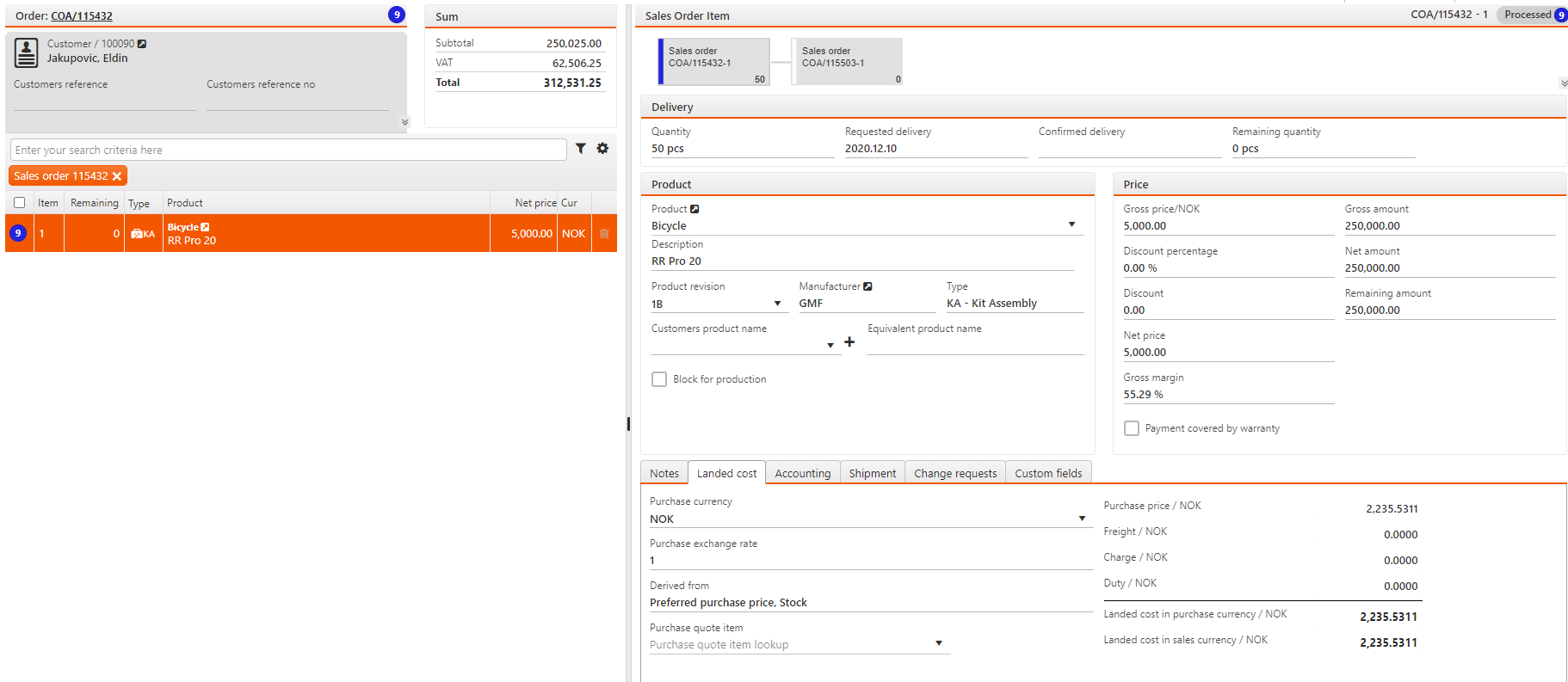

VVS Prefab uses the sales order feature in RamBase to get the project specific financial information they need. In this view they have control over the margin of the project, and how it changes in real-time as the project progresses. All items in the project are listed with individual prices and margins.

Example of the sales order view with all information to give an accurate overview of the project.

Everything in the system is connected, and examining the costs associated with the actual production is only a few clicks away. VVS Prefab can easily access the productions connected to the sales order and examine if they have exceeded planned time and material for each item. Learnings from one project can then be transported to the next project.

VVS Prefab have found the functionality of approvals connected to gross margin useful. This means that the system is set up so that specific order items with gross margin below a certain threshold value, will trigger a warning and must be approved by a supervisor. This enables VVS Prefab to always have control over their margins without managers needing to oversee all transactions.

All documentation ready at your fingertips

One of the key features in RamBase is the movement of documentation through the system.RamBase is built around the concept of documents that flow from one business process to another. For example, a request for a quote is forwarded to a quote, and then to an order and shipping advice.

Between the first quote issued to the customer and the final product produced, there has most likely been negotiations regarding price, terms, and technical specification along the way. For VVS Prefab there are several details that need to be clarified with the customer before and during a project. Especially in the engineering phase in the beginning, an incorrect assumption and the product will not work. It is therefore crucial to have a system that receives information and stores this correctly. This is especially important in deviation situations where one can easily go back and find details of any change requests that have been agreed. All this information can be stored and easily found by everybody in RamBase

Finally, when the product is ready to be shipped, the document package is only one click away with all the relevant certificates and drawings for all items in the product structure.

No need for a document controller to manually search for relevant drawings, technical specification or measurement certificates for each item, the system does that for you.