Walk, Observe, Communicate

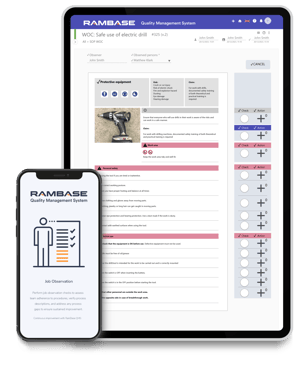

The WOC (Walk, Observe, Communicate) functionality draws inspiration from the principles of Gemba walks, where leaders immerse themselves in the workplace to gain firsthand insights to thrive for continuous improvements. WOC transforms this concept into a structured and dynamic tool integrated with the quality management processes in RamBase QMS.

WOC in practice at Hydro

At Norsk Hydro, structured shop-floor observations are driving real improvements across global operations. By using the WOC functionality in RamBase QMS, teams are able to validate SOPs, shorten feedback loops, and embed continuous improvement into daily routines.

This isn’t just about compliance — it’s about making quality a shared responsibility, from the frontline to leadership.

Explore how Hydro is using WOC to power smarter work and better performance

Key Features

The WOC functionality is a structured checklist available for all documents in our quality management system offering. By pinpointing areas for improvement, WOC supports increased productivity and efficiency.

The module encompasses the following key elements:

- Identify gaps between current and desired processes

- Discover opportunities for employee learning and skill development

- Ensure adherence to regulatory standards and internal procedures

- Facilitating targeted feedback during job observation

- Evaluate whether established procedures are truly best practice

- Log follow-up actions directly in the checklist

- Include company general checklist items for all procedures

How to use WOC

These real-life examples showcase how the WOC functionality can be a versatile and powerful tool for continuous improvement, quality assurance, and effective communication in various industries and operational contexts.

![]() Manufacturing Process Optimization

Manufacturing Process Optimization

In a manufacturing setting, WOC can be used to walk through the production floor, observing each step of the manufacturing process. Team members can use the system to document observations, identify bottlenecks, and communicate with operators in real-time. This aids in optimizing workflows, improving efficiency, and ensuring adherence to quality standards.

![]() Employee Training and Development

Employee Training and Development

WOC can play a vital role in employee training and development. Supervisors can use the system to observe employee performance, document areas for improvement, and communicate feedback in real-time. This facilitates targeted training programs and skill development initiatives based on actual on-the-job observations.

![]() Construction Site Safety Audits

Construction Site Safety Audits

WOC can be employed for safety audits on construction sites. Safety officers can walk through the site, observing adherence to safety protocols, proper usage of personal protective equipment (PPE), and identifying potential hazards. The system allows for immediate communication to address safety concerns and ensure a secure working environment.

Interested in learning more?

Bid farewell to outdated processes that no longer serve their purpose. The WOC functionality empowers real-time assessment of processes, facilitating targeted improvements and addressing specific areas requiring enhancement—all without switching to a different system.

If you're interested in exploring this feature further, reach out to us to schedule a demo and discover how WOC can help your company achieve better compliance and establish a continuous improvement culture.