Six months ago, answering a customer's order inquiry could take Angelina Persson ten minutes or more, switching between Excel files, internal systems, and production schedules to piece together a complete answer. Today, as Chief Operating Officer at Mitac, she has the same information at her fingertips in seconds.

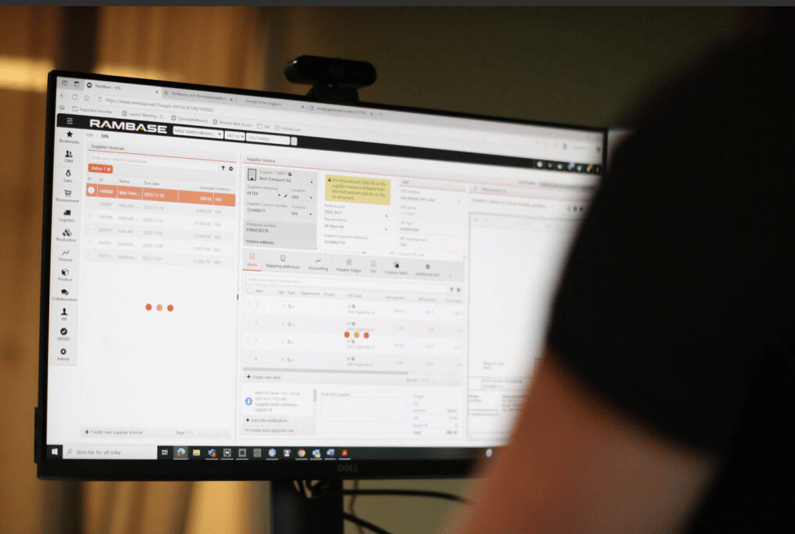

The difference? RamBase Cloud ERP.

"Everything we need is now in one place," says Persson. "Real-time data, complete traceability, instant answers. It's transformed how we operate."

For the 40-person operation, the six months since going live have been about discovering what's possible when information flows freely and everyone works from the same source of truth. This is their honest, unfiltered account of what actually happens in the first six months after flipping the switch.

The reality check: What actually changed?

From guesswork to certainty

Before RamBase, Mitac had no unified business system. Finding information meant hunting through spreadsheets, emails, and local files. The impact touched every department:

Production:

"The difference for me is enormous," says Sanna Virtanen, Production Manager. "Before, I was working with estimates and assumptions. Now I can follow the entire production flow from delivery to delivery and see reality as it actually looks."

This shift from estimation to reality changes everything. Sanna can now enter all necessary information, control exactly who sees what, and track dependencies across the entire production process.

"It's fantastic," she says. "Instead of constantly searching for information in multiple places, you now find it readily available."

The transparency has even changed how Mitac works with customers.

"It forces all of us to become more structured," Sanna adds. "And it forces customers to become more structured too."

Sanna Virtanen, Production Manager at Mitac

Sanna Virtanen, Production Manager at Mitac

Sales & Purchasing:

"I have control over things in a way I never did before," says Adam Bergqvist. "I can follow the flow and clearly see if something needs to be back-ordered from a supplier. Before, it was 'yeah, I think we have it', more guesswork. Now I can see it directly in RamBase instead of logging into several systems or emailing suppliers to ask. We don't need to think we know anymore. Now we know."

Adam Bergqvist, sales and purchasing at Mitac

This certainty eliminates an entire category of problems: promising delivery dates based on assumptions, scrambling when inventory didn't match expectations, and the downstream effects on customer trust and production schedules.

Time tracking gets real.jpg.iifHgtD6MYmv9fFjQA0A.rCuPJAMkGW.jpg?width=245&height=368&name=Stockholm%202025%20(60).jpg.iifHgtD6MYmv9fFjQA0A.rCuPJAMkGW.jpg)

One of the most tangible improvements came in time registration. Before, operators filled out paper forms without really knowing how long they'd actually spent on each part. Today, it's measurable with RamBase.

"It makes it much easier to follow up and set requirements on how long tasks should take," says Angelina. "No more guessing, just data."

This shift enables accurate job costing, reveals previously invisible bottlenecks, and provides the foundation for continuous improvement. When you know how long things actually take, you can make informed decisions about pricing, capacity, and process optimization.

Complete traceability transforms quality

The system provides end-to-end visibility: when something was purchased, when it arrived, what it's used in, and where it is in production.

"We can trace everything now," explains Angelina. "If there's a quality issue, we can find the source quickly. And we can see patterns that might indicate problems before they become major incidents. That kind of visibility was impossible before."

The cross-departmental transparency means fewer surprises. Production can now clearly see when all components have arrived and when they haven't, eliminating miscommunications that used to be routine.

"Those 'I didn't know that component wasn't coming' situations are increasingly rare," says Sanna.

The implementation philosophy: Confidence before speed

One of the most striking aspects of Mitac's journey is their deliberate pacing.

"The implementation has been a transparent process," says Angelina. "We've trained departments little by little, giving everyone time to participate, learn, and become comfortable. We moved forward slowly and deliberately—it's been a safe and good way for everyone in the organization to adopt the new system."

This phased approach created several advantages:

- Reduced resistance when people aren't overwhelmed

- Early wins that built momentum and confidence

- Organizational learning that allowed discovery of optimal workflows

- Sustainable change embedded in daily operations

For companies considering similar transitions, Mitac's approach offers a valuable counterpoint to rushed implementations. Speed matters less than sustainability.

What's next: Growing into the system

Six months in, Mitac is candid about being early in the journey. They're working on extracting comprehensive KPIs around specific efficiency gains and error reduction metrics. Those numbers will come.

But the qualitative improvements are already clear:

- Decisions happen faster because data is immediately accessible

- Miscommunications have decreased through shared visibility

- Inventory accuracy has improved from guesswork to certainty

- Customer service has strengthened through faster, more accurate responses

Perhaps most importantly, Mitac invested in RamBase early in their growth trajectory, before inefficiency became crisis.

"We didn't wait until things were broken," reflects Angelina. "This positions us to scale with confidence as demand increases, rather than playing catch-up with infrastructure."